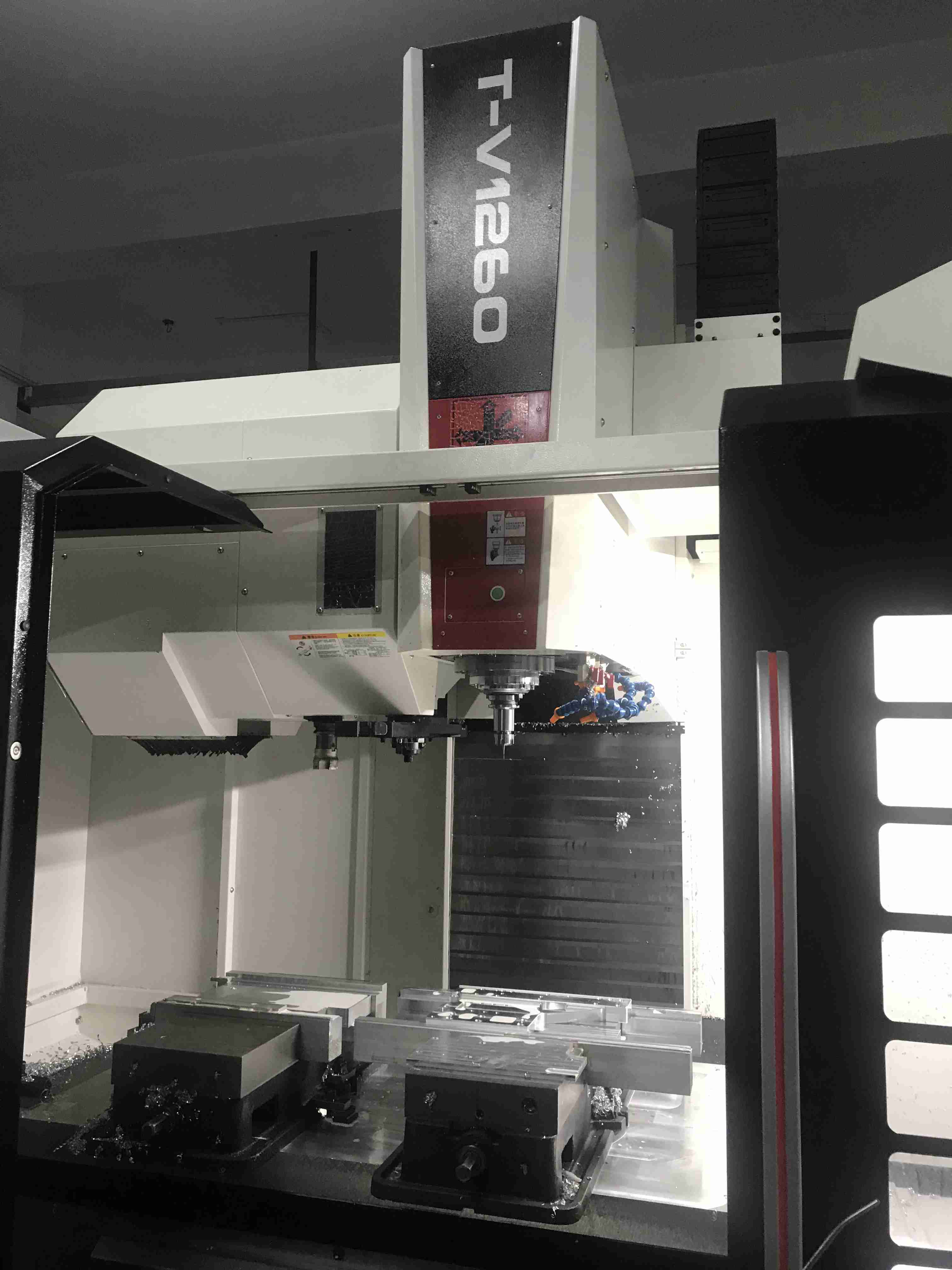

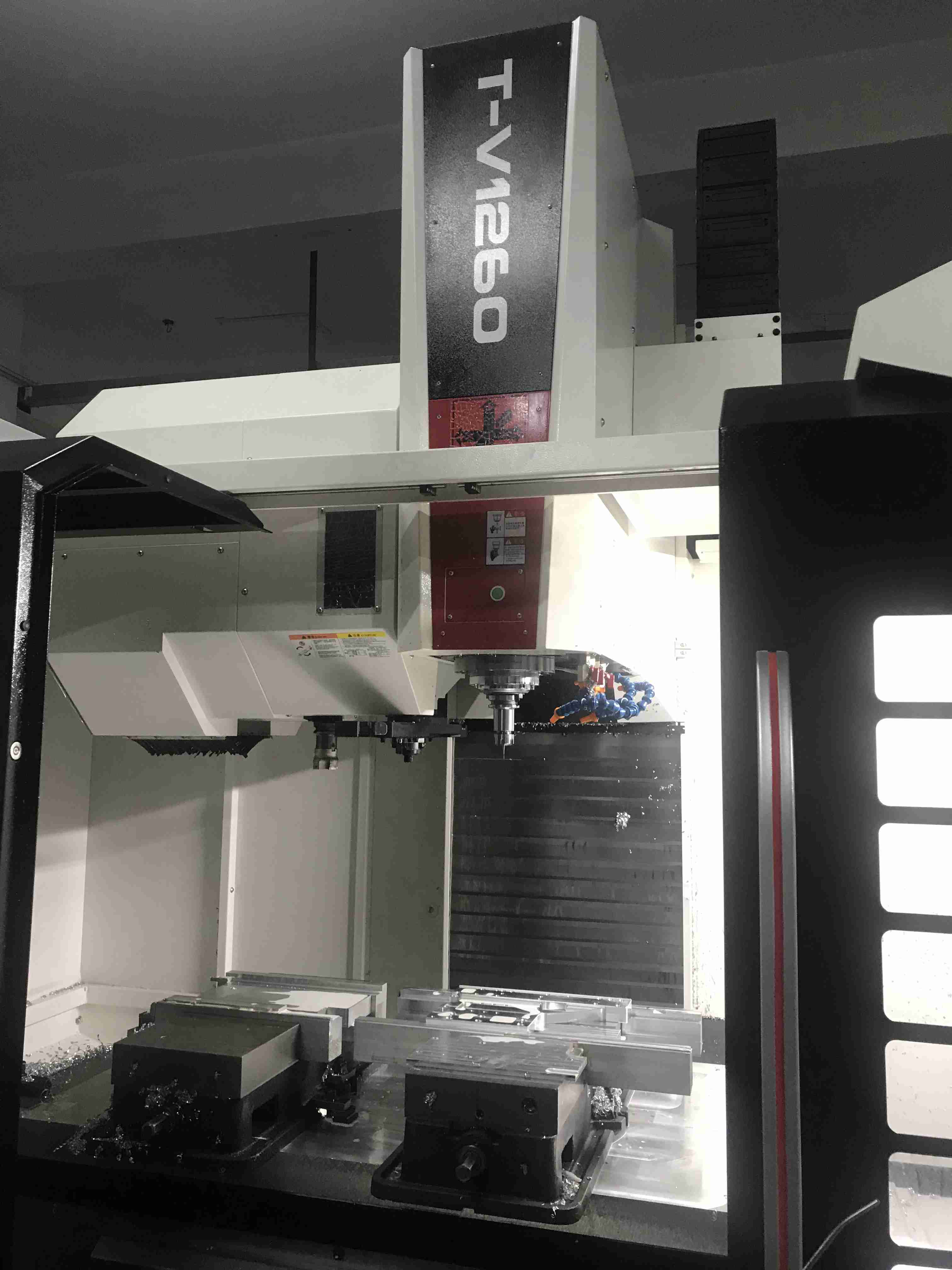

CNC Machining

CNC machining refers to machining with CNC machining tools. CNC index-controlled machine tools are programmed and controlled by CNC machining languages, usually G codes. The CNC machining G-code language tells the CNC machine tool what kind of Cartesian position coordinates the tool uses, and controls the tool's feed rate and spindle speed, as well as tool converters, coolant, and other functions. CNC machining has great advantages over manual machining. For example, the parts produced by CNC machining are very accurate and repeatable;

CNC machining can produce parts with complex shapes that cannot be manually processed. CNC machining technology has been widely promoted. Most machining workshops have CNC machining capabilities. The most common CNC machining methods in typical machining workshops are CNC milling, CNC lathe, and CNC EDM wire cutting (EDM wire cutting).

CNC machining can produce parts with complex shapes that cannot be manually processed. CNC machining technology has been widely promoted. Most machining workshops have CNC machining capabilities. The most common CNC machining methods in typical machining workshops are CNC milling, CNC lathe, and CNC EDM wire cutting (EDM wire cutting).

Service

Contact Us

Name: Kevin Hu

Tel: +86-18026978395

E-mail: [email protected]

Skype: recometaltech

WeChat: RECOMETALTECH

Whatsapp: +86 180 2697 8395

Add: Datianyang Industrial Zone,Songgang Street, Baoan District, Shenzhen,China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry