Injection Molding

Injection Molding, there are two types of it. One is for plastic parts, the other for metal parts. Metal injection molding was also called MIM.

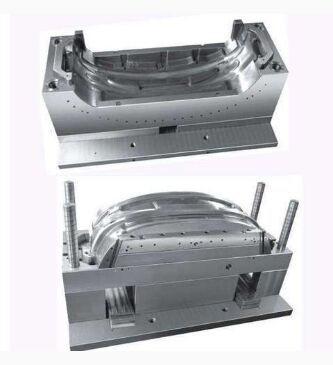

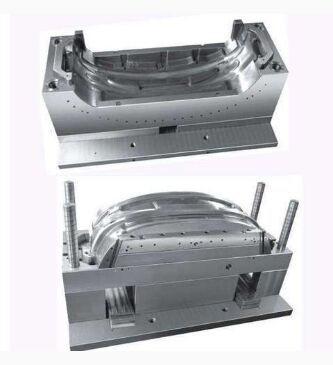

1. Plastic Injection molding process refers to the process of making molten semi-finished parts of certain shape through operations such as pressurization, injection, cooling, and separation. The injection molding process of plastic parts mainly includes 6 stages: mold clamping-filling-(gas-assisted, water-assisted) pressure holding-cooling-mold opening-demolding, etc.

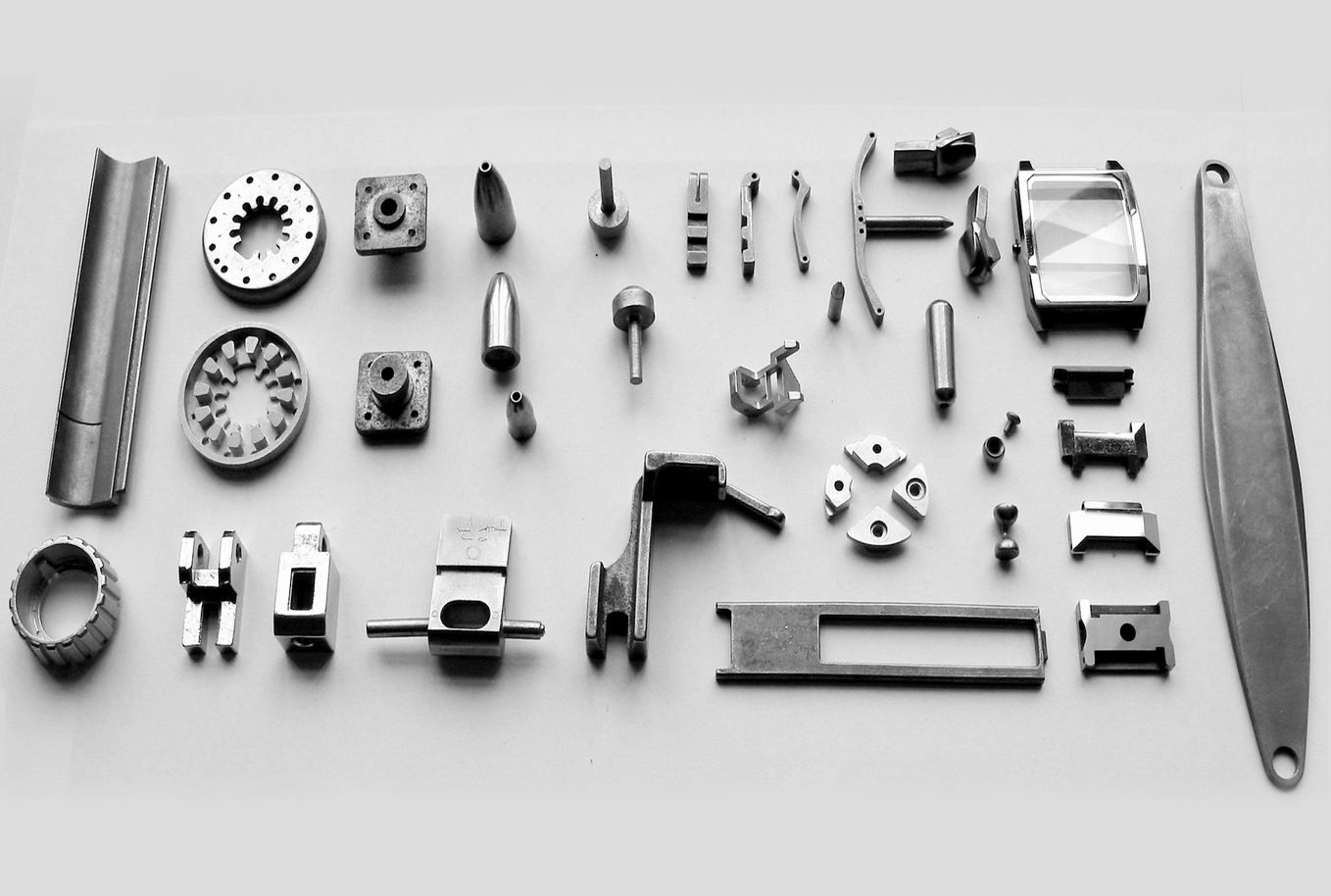

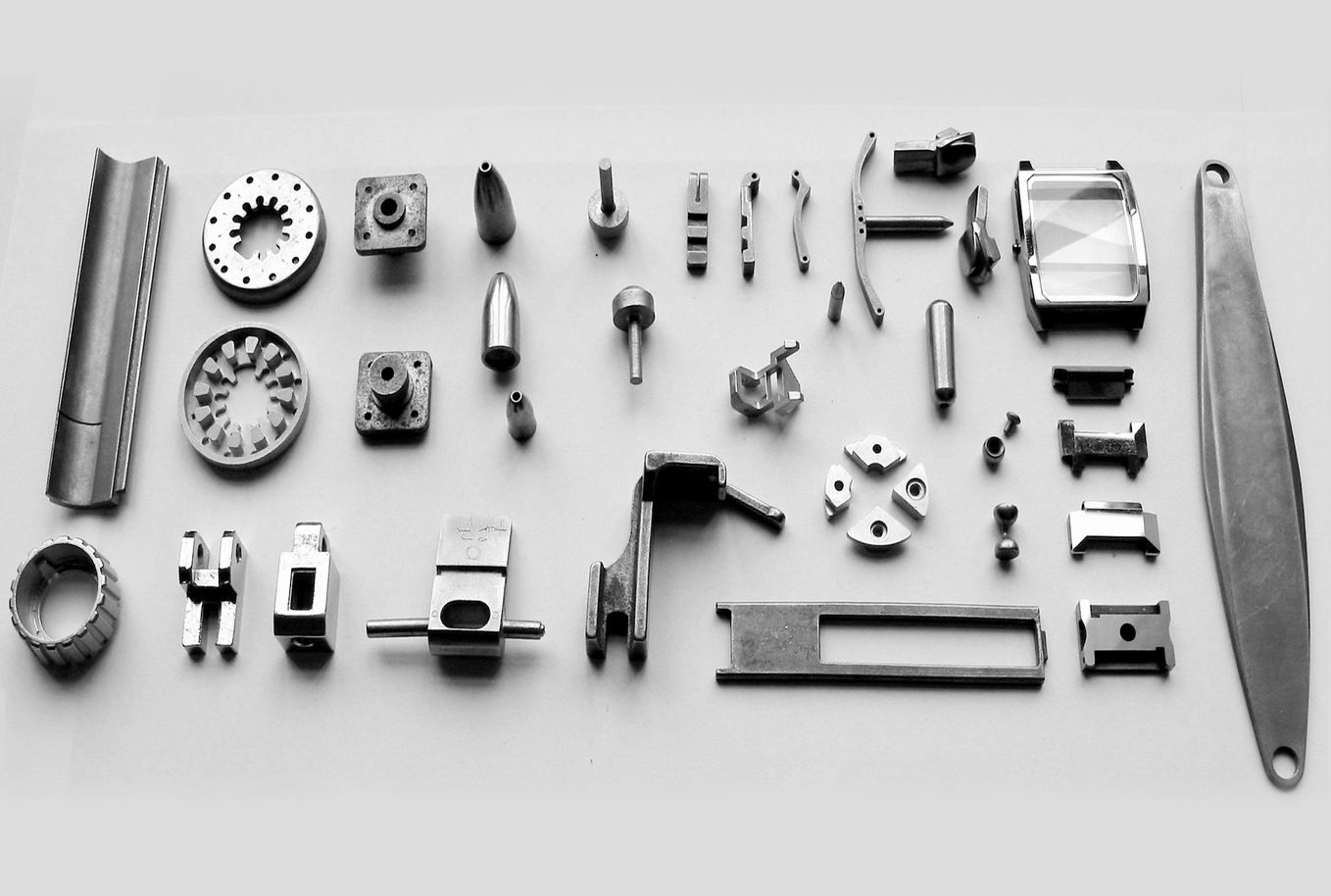

2. Metal Injection Molding (MIM) is a new type of powder metallurgy near-net forming technology that extends from the plastic injection molding industry. It is well known that plastic injection molding technology produces various complex shaped products at low prices, but plastics The strength of the product is not high. In order to improve its performance, metal or ceramic powder can be added to the plastic to obtain a product with higher strength and good wear resistance.

In recent years, this idea has evolved to maximize the content of solid particles and completely remove the binder and densify the formed compact during the subsequent sintering process. This new powder metallurgy forming method is called metal injection molding.

2. Metal Injection Molding (MIM) is a new type of powder metallurgy near-net forming technology that extends from the plastic injection molding industry. It is well known that plastic injection molding technology produces various complex shaped products at low prices, but plastics The strength of the product is not high. In order to improve its performance, metal or ceramic powder can be added to the plastic to obtain a product with higher strength and good wear resistance.

In recent years, this idea has evolved to maximize the content of solid particles and completely remove the binder and densify the formed compact during the subsequent sintering process. This new powder metallurgy forming method is called metal injection molding.

Service

Contact Us

Name: Kevin Hu

Tel: +86-18026978395

E-mail: [email protected]

Skype: recometaltech

WeChat: RECOMETALTECH

Whatsapp: +86 180 2697 8395

Add: Datianyang Industrial Zone,Songgang Street, Baoan District, Shenzhen,China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry