Aluminum Parts drilling method

Aluminum and its alloys have certain mechanical properties due to their low density

With good electrical conductivity, thermal conductivity and corrosion resistance, it is widely used in various industrial sectors, especially in the aviation field.

However, in the drilling process, aluminum alloy has many processing problems.

According to different manufacturing methods, aluminum alloys are divided into two categories: cast and deformable (rollable).

Deformed aluminum alloys are mostly used to make stretched parts, rivets, plates, profiles, etc. During the processing of this type of parts, the processing of holes is rare, and we will not consider it for the time being.

In contrast, there are many types of cast aluminum alloys, the most basic of which is that the aluminum-silicon alloy is silicon aluminum alloy.

Method of drilling aluminum alloy

Compared with steel and brass, the characteristics of aluminum alloy:

First, the material is soft and the rigidity is poor

The second is the low modulus of elasticity.

These two factors significantly affect the machinability of aluminum alloys. Therefore, when machining aluminum alloy workpieces, it is necessary to fully clamp and support the workpiece and keep the tool sharp. Otherwise, the workpiece tends to leave the cutting tool.

Sometimes irregular groove marks and bright extrusion spots appear on the surface of the workpiece. One may be caused by the abnormal pressure of the tool on the workpiece, and another may be caused by the vibration caused by the unstable clamping. The surface of the workpiece is rubbed in a gap type, and squeezing phenomenon and powdery cutting occur. Then when the gap or elasticity disappears, the tool bites into the surface of the workpiece and gnaws out groove marks.

Therefore, during the drilling process, we must also pay attention to the cutting of aluminum alloy

To cut the main points, reasonably select the cutting method of aluminum alloy.

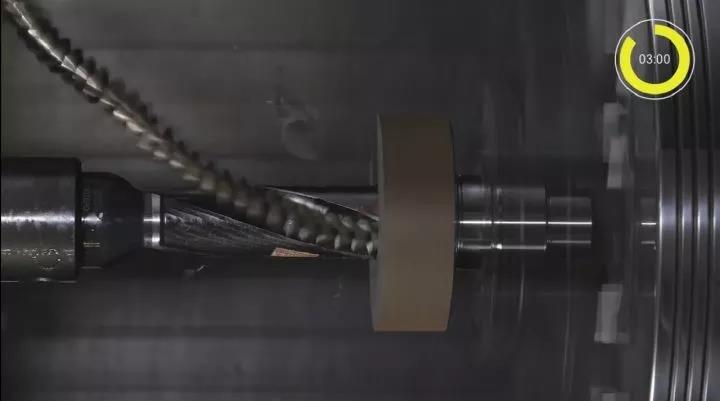

Choose aluminum alloy group drill

During the drilling process, the standard group drill has relatively large outer edge angle (2Φ), inner edge angle (2Φ'), and small relief angle (α), causing serious friction between the flank surface and the cut surface. A lot of cutting heat, the cutting temperature rises quickly; the main cutting edge has a small cutting angle to the material, and the cutting thickness becomes thinner, which is easy to break and difficult to discharge; the rake angle of the inner edge is negative, and it is completely in the state of extrusion cutting during work. The local temperature is high and the material melting is serious.

Improvement of geometric parameters and shape of special aluminum alloy group drills. After long-term practice, we have improved the geometric parameters and shape of the standard group drill, sharpened it into a special drill bit for aluminum alloy, and reduced the original 140° outer edge angle to 105°~110°, thus reducing The axial force increases the tool nose angle, improves the heat dissipation conditions, and aggravates the chip deformation, forming strip-shaped chips.

Increase the relief angle, and increase the relief angle α from the original 13°~14° to 22°~23°, which reduces the generation of cutting heat and reduces the welding phenomenon. At the same time, the larger relief angle also makes The main cutting edge is sharper, it is easier to cut into the material, and form thick chips for easy discharge.

Changing the original rake angle of –10° to a positive value or close to a positive value can reduce the cutting resistance and improve the cutting shape of the inner blade.

Changing the original two-sided arc grooves to single-sided arc grooves can reduce the cutting resistance and increase the chip thickness without causing vibration under the condition of low aluminum alloy hardness.

Grind off the chisel edge along the edge on the back side to increase the chip space.

2) Sharpening method of aluminum alloy group drill. Prepare to use A46~60K, L model grinding wheels, the grinding wheel is smoothed, and the outer suburb of the grinding wheel should not be larger than the arc radius of the drill bit.

When sharpening a straight edge, the cutting edge of the drill is aligned with the plane of the grinding wheel, and the axis of the drill is to the left to cut the peak angle of the chip. Grind from the cutting edge to the flank face, swing the shank up and down, and have a fulcrum during the whole process. The tail swing cannot be higher than the horizontal plane.

When sharpening the crescent socket, the main cutting edge of the drill touches the corner of the grinding wheel. The cutting edge must not be upturned. The shank of the drill bit is pressed down to sharpen the flank. The angle between the grinding wheel and the drill shaft is 55°. swing.

When chiseling, the axis of the drill bit is inclined 15° to the left, and the tail of the drill bit is pressed down by 55°. The outer edge and the side of the grinding wheel form an angle. Please cool the bit in time to avoid core annealing.

Finally, sharpen and deepen the inner groove of the drill bit. Use a sheet grinding wheel or a small grinding wheel. At this time, pay attention to the angle of the relief angle to avoid the position of the flank surface space higher than the arc cutting edge.

Snare of the cutting edge

In order to reduce the occurrence of built-up edge, especially to prevent the residual mark when the built-up edge disappears from sticking to the front, the rake surface (spiral groove) and flank surface of the drill cutting edge should be polished to 0.8 with oil stone More than μm; it is best to use a drill with polished grooves.

Choose the right cutting amount

Limiting speed and large feed are the cutting principles of aluminum alloy drilling. High speed can provide greater centrifugal force, making it easier for the chips to be ejected in the spiral groove in a spray-like manner. At the same time, it can also shorten the unit residence time of the chips on the cutting edge and reduce the possibility of sticking. And a larger feed rate can reduce the cutting heat generated per unit cutting amount.

Fully clamp and support the workpiece

When machining aluminum alloy workpieces, the workpiece must be fully clamped and supported, and the tool must be kept sharp. Otherwise, the workpiece tends to leave the cutting tool.

Sometimes irregular groove marks and bright extrusion spots appear on the surface of the workpiece. One may be caused by the abnormal pressure of the tool on the workpiece, and another may be caused by the vibration caused by the unstable clamping. The surface of the workpiece is rubbed in a gap type, and extrusion and powdery cutting occur. Then, when the gap or elasticity disappears, the tool bites into the surface of the workpiece and gnaws out the groove.

Choose a reasonable process

In order to obtain a smooth surface of the workpiece, the combination of drilling and reaming is used as much as possible, because various qualified aluminum alloy workpiece blanks will always have some oxide layers, which will aggravate the wear of the drill.

Choose the matching cutting fluid

The choice of aluminum alloy cutting fluid is very important, and good lubricity, cooling, filtering and rust resistance must be guaranteed. Therefore, the cutting fluid that can be used for aluminum alloy processing is different from ordinary cutting fluids.

When drilling, because it is high-speed machining, a lot of heat can be generated. If the generated heat cannot be taken away by the cutting fluid in time, tool sticking will occur, and in severe cases, built-up edge will occur, which will seriously affect the workpiece. The processing finish roughness and the service life of the tool, and the heat can also deform the workpiece, which seriously affects the accuracy of the workpiece.

Therefore, the choice of cutting fluid must consider its own lubrication

The cooling performance should also be considered. For finishing, it is advisable to choose emulsified anti-friction cutting fluid or low-viscosity cutting oil; for semi-finishing and rough machining, choose low-concentration emulsified anti-friction cutting fluid, or semi-synthetic anti-friction cutting fluid with good cooling Performance cutting fluid.

Latest News

Contact Us

Name: Kevin Hu

Tel: +86-18026978395

E-mail: [email protected]

Skype: recometaltech

WeChat: RECOMETALTECH

Whatsapp: +86 180 2697 8395

Add: Datianyang Industrial Zone,Songgang Street, Baoan District, Shenzhen,China.

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry